Low production costs, ever increasing demand and the popularity of molded products have created a big revolution in China. For a Plastic Molding Manufacturer, these three factors have become the source of tremendous gains. By selling their plastic molded products to various parts of the world, these manufacturers have been part of a real revolution in the market. Going by the sales data of these products, one can easily say that plastic products are a very big hit all over the world. They produce, they sell and they produce even more. This has been the mantra of success of these plastic products. In order to understand the secret behind their fame, one has to dig into the manufacturing details of these plastic products.

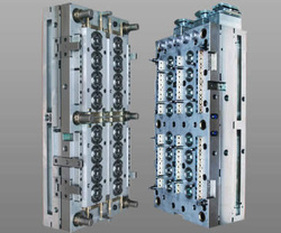

The secret recipe behind the large production of plastic mold products is that the machinery available for production is unique and advanced. Production speeds have become lightening fast producing tons and tons of molded plastic stuff. Innovative designs of molds, instruments with latest softwares and experienced workforce have been the key to this unbelievable increase in profits of these manufacturers. Tough competition in the market has led to lowering of costs of the finished products. This has made the products to be sold like hot cakes. Continuous research is being carried out to develop novel production tools which will enable an even faster and economical route for the production of these articles. Armed with all these positive factors, the plastic molding industry is going to serve the needs of various other industries for years to come. For More Information visit Our Site: - http://www.china-plastic-molding.com/

The secret recipe behind the large production of plastic mold products is that the machinery available for production is unique and advanced. Production speeds have become lightening fast producing tons and tons of molded plastic stuff. Innovative designs of molds, instruments with latest softwares and experienced workforce have been the key to this unbelievable increase in profits of these manufacturers. Tough competition in the market has led to lowering of costs of the finished products. This has made the products to be sold like hot cakes. Continuous research is being carried out to develop novel production tools which will enable an even faster and economical route for the production of these articles. Armed with all these positive factors, the plastic molding industry is going to serve the needs of various other industries for years to come. For More Information visit Our Site: - http://www.china-plastic-molding.com/

RSS Feed

RSS Feed